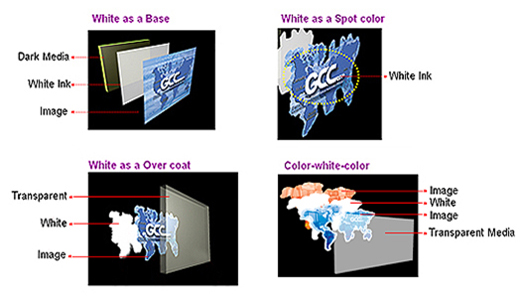

| Varnish is a transparent spread on the surfaces of printed matters (images) that forms a thin and even transparent gloss layer after its leveling and UV curing for drying process. Varnish not only protects printed content but enhances durability. Different varnish modes are available that offer the advantages of a high value added application and cost saving on labor and laminator equipment as well as creates the tactile attribute of graphics, which lifts the added value of products and presents eye-catching printing effect.

The features of the varnish modes are:

Gloss: The graphic is made to be glossy Semi gloss: The graphic is made to be semi glossy Matte: The graphic is made to have a matte surface Water mark: The graphic is made to be glossy with watermarks

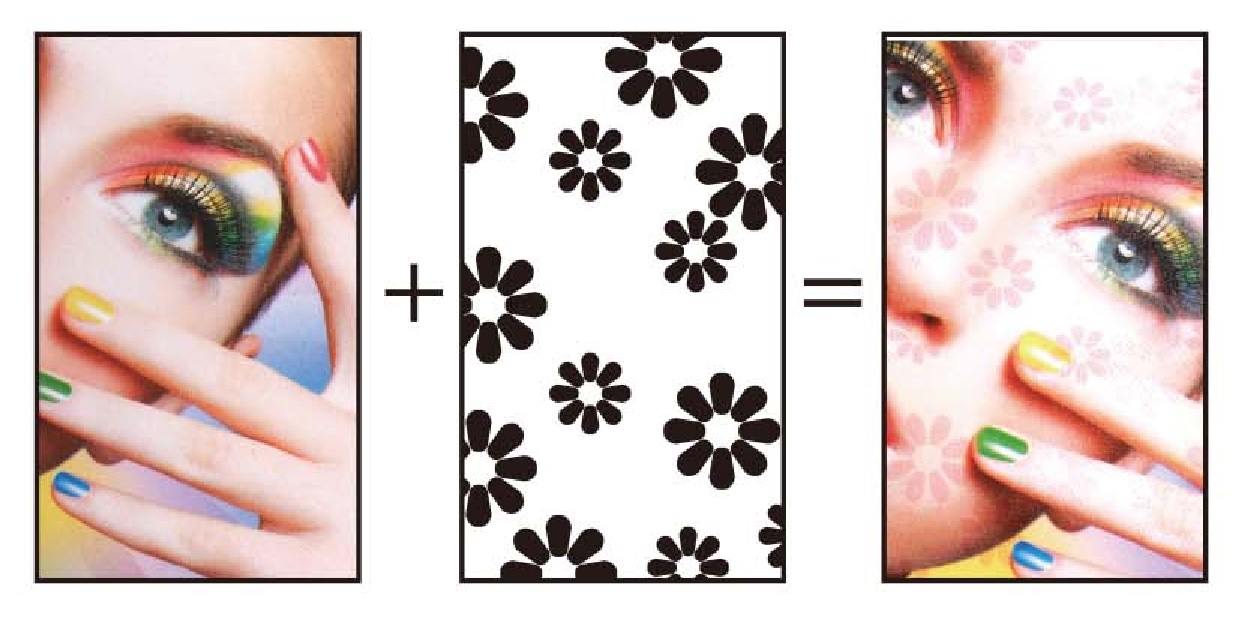

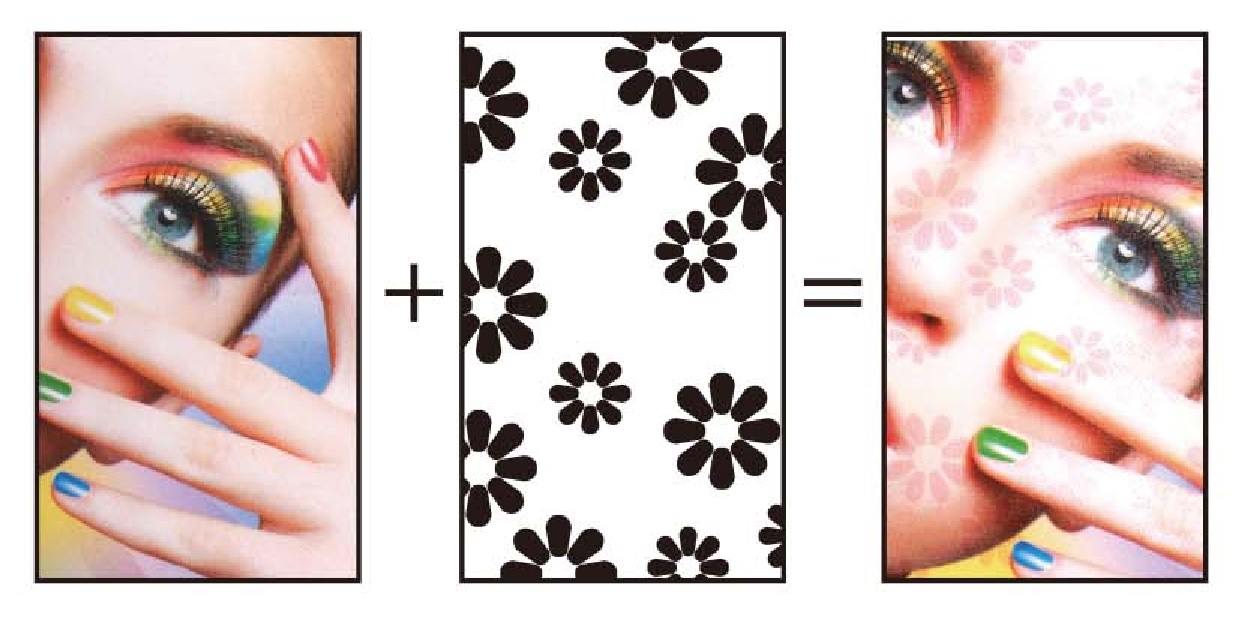

By adjusting the spray printing control of color inks and varnish inks, color varnish can be applied to printed matters to satisfy a wide range of applications. This advanced technology is an excellent tool for color customization which fully exhibits the highlighted effects and practical value of the combination of varnish and patterns on printed matters.

32 ready-to-use patterns are available or you may create your tailor-made pattern make your printed matters appealing and unique.

|