|

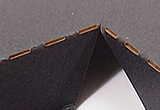

Unique Fiber Laser Source with Exquisite Cutting Capability |

| World leading fiber laser source with unique laser firing mode control meets variety metal sheets processing demand. Powerful cutting capability to handle up to 3mm thick stainless steel and high reflective metals (aluminum, copper) with clear edge now possible. |

|

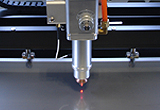

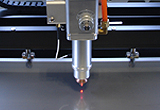

| Capacitive Cutting Head with Autofocus |

|

| Precise Capacitor Cutting Head keeps consistent focal distance between cutting head and heat deformed material to obtain consistent cutting quality over the platform. The non-contact cutting procedure prevents scratch on the materials to create clean cutting edge. |

|

|

RoHS Compliance |

| All GCC products are RoHS-compliant (the European Parliament Directive 2002/ 95/ EC, Restriction of Hazardous Substances) and lead-free (pb free). GCC will continue to concern and provide environmentally friendly products to protect the earth for our further generation. |

|

| Drag-N-Play |

|

| The “Drag-N-Play” feature greatly reduces complex set up procedures and allows users to directly drag the lens carriage to the starting point of a job. |

|

|

DuraGuide™ Motion Design |

| Systematic and reliable motion system embedded with strong mechanical framework, reinforced Kevlar belts, and accurate servomotor control technology to deliver superb output quality. SmartSEAL™ dust protection design to keep dust from the motion system to reduce daily maintenance and prolong rail’s life cycle. |

|

| Closed-loop DC Servo Technology |

|

| A Closed-loop DC servo motor can deliver greater continuous shaft power at higher speeds than a stepper of the same frame size. In addition, It can also give far greater accuracy due to closed-loop position feedback and the continuous movement, instead of constant stopping and starting. GCC LaserPro high speed closed-loop DC servo motor technology guarantees precise and fast carriage movement with exceptionally accurate outputs. |

|

|

Automatic Table to Load up to 120 mm (4.7″) Thick Objects |

| The automatic table movement can allow to load thick working objects and diversify the application possibility. |

|

| Built-In Networking Connection |

|

| Network connection enables multiple laser engravers to be operated by one PC and multiple PCs to share a single unit of laser engraver. The Ethernet port has made data transmission easier and faster for GCC LaserPro users using network connection. Free your designers with great flexibility and maximum machine versatility. |

|

|

Programmable Origin Modes |

| Easy-to-use multiple position modes allow the operators an effortless way to setup a job with Drag-N- Play. Repetitive workflows can be drastically simplified by relocating the origin position to any desired location. |

|

| Intuitive Control Panel Interface |

|

| A user-friendly menu-driven interface system simplifies complex tasks. Hot keys design and job status display facilitates your work and makes it clear and easy to carry out. |

|

|

Innovative Windows Driver |

| Directly output from familiar designing software like Illustrator, CorelDraw, AutoCad through GCC LaserPro Windows driver. The innovative driver featuring powerful functions, such as SmartCENTER, Bridge Cutting, Drill, and more to reduce set up time and make easy adjustments to achieve marvelous output quality. |

|

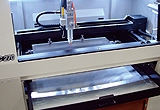

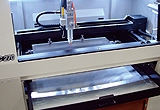

| Collecting Drawer |

|

| It is a convenient design for users to collect completed workpieces and clean scrap easily. |

|

|

SmartLIGHT |

| Built-in LED light module illuminates the working space and makes every detail easy to see. |

|

| Key Switch & Emergency Stop |

|

| Key switch safeguards the machine from unauthorized use. Prominent emergency button located on the top of the machine allows operators to stop the laser and the motion carriage immediately to provide a safe operating environment. |

|

|

Job Preview Function |

The GCC LaserPro laser engraver all series printer driver features a job preview function that previews graphics before the official laser printing process. One of the highlights of this feature is that it provides an estimated working time*.

The estimated working time is an easy tool for operators to know in advance as how much time will be needed to finish the job for better job management; it is also convenient for a shop to provide a quotation for its laser services. |

|

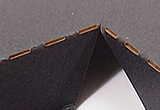

| Bridge Cutting |

|

| Bridge Cutting function diversifies the laser cutting into packaging prototyping and fulfill versatile requirements. Define the cutting gap to create the dashed line effect from user friendly print driver interface. |

|

|

Pass-through Front to Rear Doors (Optional) |

| A design with doors on both ends to accommodate extremely long working pieces, front door without the need for a screwdriver. |

|

– For USB storage (Max. 32GB capacity, FAT file system)

– For USB storage (Max. 32GB capacity, FAT file system) – For connecting with the computer

– For connecting with the computer