| LabelExpress |

LE15 |

| Model Number |

LE15-20V93 |

LE15-30V |

LE15-25Vi102 |

| Cutting Width |

381 mm (15″) |

| Work Area (Sheet) (W x L) |

381 x 500 mm (15″ x 19.7″) |

| Max. Label Graphic Size |

381 x 330 mm (15” x 13”) |

| Max. Part Size (W x L x H) |

Width |

400 mm (15.7″) |

| Roll size |

76.2 mm (3″) core with 300 mm (11.8″) diameter |

| Roll Weight |

25 kgs |

| Laser Source |

Sealed CO2 Laser |

| Wattage |

20W 9.3-μm |

30W 10.6-μm |

| Drive |

Closed-loop DC Servo Control |

| Roll to Roll |

Stepper motor Control |

| Maximum Speed |

1,530 mm/s (60ips) (for straight line cutting) |

| Speed Control |

Adjustable from 0.1~100 %

(Up to 16 color-linked speed settings per job |

| Power Control |

Adjustable from 0~100%

( Up to 16 color-linked power settings per job ) |

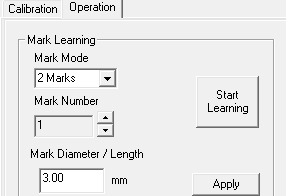

| Alignment System |

CCD Module |

| Distance Accuracy |

0.254 mm or 0.1% of move, whichever is greater |

| Computer interface |

Standard USB port |

| Operating systems |

MS Windows |

| Display Panel |

4-line LCD panel |

| Paper Feeding |

Auto feed sensor, re-winding system, paper alignment control,

waste removal system |

| Vacuum System |

Down vacuum for media fixation |

| Top vacuum for media surface cleaning |

| Process materials |

Paper, PET, PP, BOPP, etc. |

| Safety |

Class IV Laser Product Compliant with EN60825-1:2014

Class IV Laser Product Compliant with CDRH |

| Dimensions (W x L x H) |

Machine |

1,070 x 1,441 x 1,180 mm

(42.2 x 56.7 x 46.5 in.)

|

| Shipping |

1,320 x 1,660 x 1,490 mm

(52 x 65.4 x 58.7 in.) |

| Weight |

Machine |

250 kg |

| Shipping |

385 kg |

| Facility Requirements |

| Electrical |

100~240 Volt AC, 50/ 60Hz, Auto Switching, Max. 10 Amp |

| Power Consumption |

MAX:1000W |

| Air Exhaust System (Optional) |

External exhaust system required (Air Flow: 1000~1500m3/h) |

| Compressor (Optional) |

Air Compressor required (Air Capacity: 64~81L/min) |

| Optional (LabelExpress Laminator) |

| Lamination width |

MAX: 380mm (15”) |

| Lamination Film (outer diameter) |

MAX: 250mm (9.8″), with core 76.2mm (3″) |

| Media (outer diameter) |

MAX: 300mm (11.8″), with core 76.2mm (3″) |