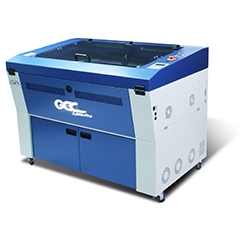

| Spirit GLS |

|

| Work Area |

34 x 24 in. (860 x 610 mm) Extendable to 38 x 24 in. (960 x 610 mm) |

|

Max. Part Size

(L x W x H)

|

All doors closed |

39 x 25 x 7 in. (990 x 635 x 177 mm) |

| All doors open |

39 x ∞ x 7 in. (990 x ∞ x 177 mm) |

| Table Size |

40.3 x 27.7 in. (1025 x 705 mm) |

| Dimensions |

53.7 x 34.6 x 39.7 in. (1365 x 880 x 1010 mm) |

| Laser Source |

30 to 100W 10.6-μm sealed CO2 Laser / 20W & 60W 9.3-μm sealed CO2 Laser |

| Cooling |

Air-cooled, Operating environment temperature 15°-30°C (60°-86°F) |

| Drive |

Closed-loop DC Servo Control |

| Maximum Motor Speed |

80 IPS |

| Speed Control |

Adjustable from 0.1~100% (Up to 16 color-linked speed settings per job) |

| Power Control |

Adjustable from 0~100% (Up to 16 color-linked power settings per job) |

| Engraving capability |

256-level gray scale image processing capability |

| Distance Accuracy |

0.254 mm or 0.1% of move, whichever is greater |

| Z-Axis Movement |

Automatic |

| Focus Lens |

Standard 2.0″, optional 1.5″, 2.5″, & 4.0″ available |

| Resolution (DPI) |

Available 125, 250, 300, 380, 500, 600, 760, 1000, 1500 |

| Interface |

10 Base-T Ethernet

USB Type-A 2.0  – For USB storage (Max. 32GB capacity, FAT file system) – For USB storage (Max. 32GB capacity, FAT file system)

USB Type-B 2.0  – For connecting with the computer – For connecting with the computer |

| Compatible Operating Systems |

MS Windows |

| Display Panel |

4-line LCD display showing current file name, total working time, laser power, engraving speed, file(s) loaded into memory buffer, setup and diagnostic menus |

| Safety |

Class I Laser Product Compliant with EN60825

Class II Laser Product Compliant with CDRH

2006/42/EC Machinery Directive Compliance

Class 4 Laser Product Compliant with CDRH with the optional pass-through door module |

| Facility Requirements |

|

| Operation Voltage |

Laser below 80Watt, 100-240VAC, 50-60Hz Auto Switching, Max. 15A

Laser 80Watt and above, 200-240VAC, 50-60Hz, Max. 15A |

| Fume Extraction System |

External exhaust system with minimum flow rate 800m3/h (CFM 471 ft3/h) is required,2.3kPA negative pressure (Pure-Air PA-1500FS @ 4″ exhaust port) |

|

– For USB storage (Max. 32GB capacity, FAT file system)

– For USB storage (Max. 32GB capacity, FAT file system) – For connecting with the computer

– For connecting with the computer