| T500 |

|

| Laser Wattage |

60 W |

80 W |

100W |

150 W |

200 W |

| Laser Source |

Sealed CO2 Laser |

| Cooling |

Air-cooled |

Water-cooled |

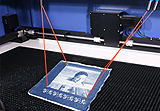

| Work Area |

51 x 35 in. (1300 x 905 mm) |

|

Max. Part Size

(L x W x H)

|

w/o cutting table |

53 x 36 x 5 in. (1346 x 916 x 127 mm) with 2″/4″ lens53 x 36 x 3 in. (1346 x 916 x 76.2 mm) with 6″ lens |

| All doors open |

53 x ∞ x 1 in. (1346 x ∞ x 25 mm) with 2″/4″ lens |

| With cutting table |

52 x 35 x 4.4 in. (1325 x 889 x 114 mm) with 2″/4″ lens |

| 52 x 35 x 1.5 in. (1325 x 889 x 38 mm) with 6″ lens |

| Dimensions |

71.6 x 49.2 x 52.3 in. (1820 x 1250 x 1330 mm) |

| Weight |

420 Kg / 924 lb |

440 Kg / 968 lb |

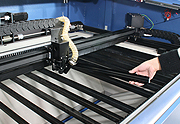

| Drive |

AC servo Control |

| Maximum Speed* |

40IPS |

| Speed Control |

Adjustable from 0.1-100% (Up to 16 color-linked speed settings per job) |

| Power Control |

Adjustable from 0-100% (Up to 16 color-linked power settings per job) |

| Engraving capability |

256-level gray scale image processing capability |

| Distance Accuracy |

0.254mm or 0.1% of move, whichever is greater |

| Z-Axis Movement |

Manual |

| Resolution (DPI) |

Available125, 250, 300, 380, 500, 600,760,1000, 1500 |

| Interface |

10 Base-T Ethernet

USB Type-A 2.0  – For USB storage (Max. 32GB capacity, FAT file system) – For USB storage (Max. 32GB capacity, FAT file system)

USB Type-B 2.0  – For connecting with the computer – For connecting with the computer |

| Focus Lens |

Standard 4″ focal lens in enclosed lens carriage (Optional 2″/6″ lens ) |

Standard 6″ focal lens in enclosed lens carriage (Optional 2″/4″ lens ) |

| Display PanelDisplay Panel |

4-line LCD panel showing current file name, total working time, laser power, engraving speed, file(s) loaded into memory buffer, setup and diagnostic menus. |

| Safety |

Class I Laser Product Compliant with EN60825

Class II Laser Product Compliant with CDRH

2006/42/EC Machinery Directive Compliance

Class 4 Laser Product Compliant with CDRH with the optional pass-through door module |

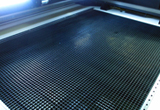

| Cutting Table |

Knife-shaped cutting barswith alumminum grid cutting table |

| Facility Requirements |

|

| Operation Voltage |

200-240VAC. 50/60Hz auto switching, Max.15A |

200-240VAC. 50/60Hz auto switching, Max. 25A |

200-240VAC. 50/60Hz auto switching, Max. 30A |

| Fume Extraction System |

External exhaust system with minimum flow rate 2160m3/h (CFM 1273 ft3/h) is required,

2.5kPA negative pressure (Pure-Air PA-2400FS @ 8″ exhaust port)

|

– For USB storage (Max. 32GB capacity, FAT file system)

– For USB storage (Max. 32GB capacity, FAT file system) – For connecting with the computer

– For connecting with the computer